[ad_1]

googletag.cmd.push(function() {

var gptSlot = googletag.defineSlot(‘/21776187881/FW-Responsive-Main_Content-Slot1’, [[728, 90], [468, 60], [300, 100], [320, 50]], ‘div-gpt-ad-b1-i-fw-ad-1’).defineSizeMapping(gptSizeMaps.banner1).setCollapseEmptyDiv(true).addService(googletag.pubads());

gptAdSlots.push(gptSlot);

});

googletag.cmd.push(function() { googletag.display(‘div-gpt-ad-b1-i-fw-ad-1’); });

Third-party logistics provider ITS Logistics in its August report is warning clients of capacity issues both on the road and rails.

“We have been calling the lack of ocean chassis availability for months,” Brashier said. “This problem has metastasized due to the volumes of containers being finally moved out of British Columbia to the ramps in Chicago and the Midwest. The pain is real for our clients. The effects of this will be significant increases in ramp storage and transportation costs and potential line down situations.”

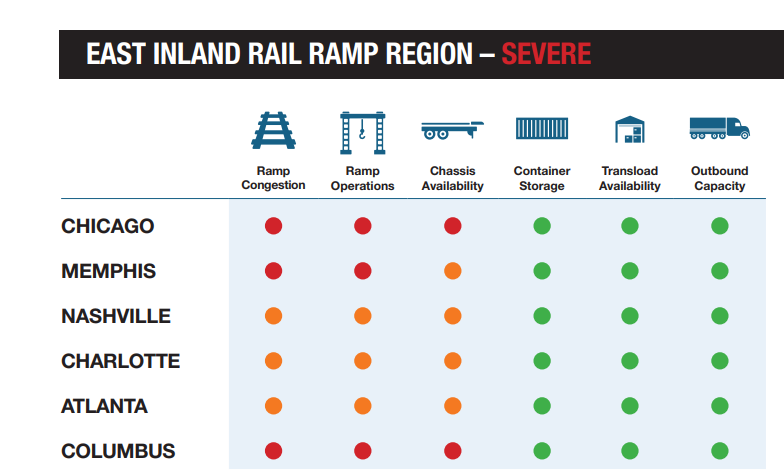

Breaking out the rails, ITS has put the East Coast ramps in the “severe category,” citing congestion at the ramps both in operations and chassis availability.

Paul Brashier, vice president of drayage at ITS Logistics, says the lack of ocean chassis equipment and increased volumes will cause significant operational issues and create additional costs.

As a result of the congestion, ITS says it will be imperative for companies to consider avoiding booking low-inventory or high-demand SKUs to the ramps of the Midwest. It is also urging clients to instead move some volumes to be transloaded and moved inland via truckload or intermodal.

This is why visibility technology is so important, Brashier added. “It enables you to have time to make decisions. The deeper you can get a line of sight into future client demand and the current state of equipment supply and operations, helps you be nimble in terms of how to pivot.”

window.googletag = window.googletag || {cmd: []};

googletag.cmd.push(function() {

googletag.defineSlot(‘/21776187881/fw-responsive-main_content-slot2’, [[468, 60], [728, 90], [300, 100], [320, 50]], ‘div-gpt-ad-1665767472470-0’).defineSizeMapping(gptSizeMaps.banner1).addService(googletag.pubads());

googletag.pubads().enableSingleRequest();

googletag.pubads().collapseEmptyDivs();

googletag.enableServices();

});

googletag.cmd.push(function() { googletag.display(‘div-gpt-ad-1665767472470-0’); });

While the other ramps around the country are all signaled green, there is a caveat with the Pacific inland ramp region.

In the operating efficiencies category, ITS warned about the potential for some displaced volumes as a result of BCO/shipper change of bookings for IPI freight to avoid western Canada. The 14-day west coast Canadian ports strike in July created massive delays and container congestion. The Railway Association of Canada has said that delays are on the upper end of the 42-to70-day range to clear out the congestion.

Over the roads — given Yellow’s bankruptcy and the lack of freight volumes — ITS said it is keeping a close eye on the increased likelihood of trucking capacity exiting the marketplace “at an alarming rate.” It added that during this slower time in freight, shippers should use the time wisely and vet the health of their smaller dray providers and look at augmenting their trucking with an aggregate of companies.

“Supply chains are at risk when shippers only look at price,” Brashier warned. “Shippers need to make sure their RFP provides more value than the cheapest rate. Operations also need to be reviewed and considered.”

The post Viewpoint: A tale of 2 capacities appeared first on FreightWaves.

[ad_2]

Source link